Butt Fusion HDPE Fittings are the most economical type of Fittings used in HDPE Pipes, These Fittings are joined with HDPE Pipes by Butt Fusion Method, Trained Manpower is required to Join these Fittings with HDPE Pipes as Best and Strong Joint depends on various factors like Proper Heating Temperature, Heating Time, Changeover time and Correct Pressure etc. Size Range of HDPE Butt Fusion Type Fittings is from 50 mm OD to 200 mm OD, Pressure Rating from PN 6 to PN 16. These Fittings should not should be used less than 50 mm OD Pipe Size, as inner ring formed during Butt Fusion Joint further reduces the internal diameter of HDPE Pipe and restricts flow. HDPE Fittings are available as per Indian Standards like IS 8008, IS 8360,and as per International Standards. All the Fittings are manufactured using virgin raw material only.

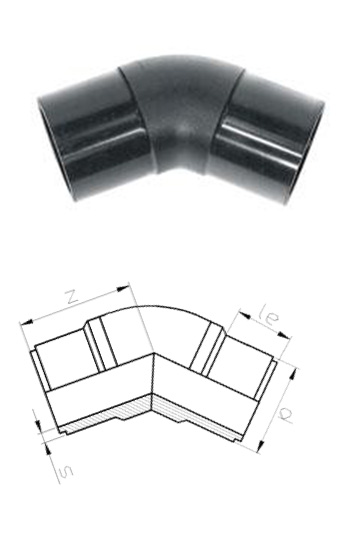

Elbow 45° – HDPE

Specifications – PE 100, PN 16, SDR 11, S5

Butt welding, injection molded

| d (mm) | le (mm) | z (mm) | s (mm) | Weight kg/pc |

|---|---|---|---|---|

| 90 | 81 | 120 | 8.2 | 0.540 |

| 110 | 86 | 130 | 10 | 0.950 |

| 125 | 93 | 140 | 11.4 | 1.260 |

| 140 | 97 | 150 | 12.7 | 1.700 |

| 160 | 103 | 160 | 14.5 | 2.400 |

| 180 | 110 | 170 | 16.4 | 3.200 |

| 200 | 117 | 185 | 18.2 | 4.500 |

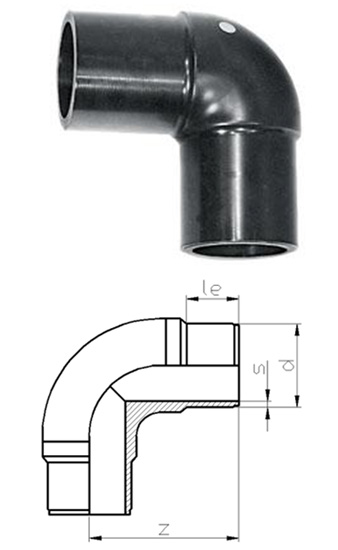

Elbow 90° – HDPE

Specifications – PE 100, PN 10, SDR 17, S8

Butt welding, injection molded

| d (mm) | le (mm) | z (mm) | s (mm) | Weight kg/pc |

|---|---|---|---|---|

| 90 | 81 | 150 | 5.4 | 0.790 |

| 110 | 86 | 165 | 6.6 | 0.830 |

| 125 | 93 | 180 | 7.4 | 1.100 |

| 140 | 97 | 190 | 8.3 | 1.550 |

| 160 | 103 | 210 | 9.5 | 2.100 |

| 180 | 110 | 232 | 10.5 | 2.800 |

| 200 | 117 | 253 | 11.7 | 3.900 |

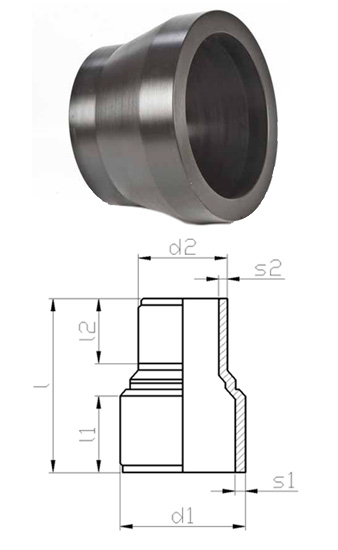

Reducer – HDPE

Specifications – PE 100, PN 16, SDR 11, S5

Butt welding, injection molded

| d1/d2 (mm) | l (mm) | l1 (mm) | l2 (mm) | s1 | s2 | Weight kg/pc |

|---|---|---|---|---|---|---|

| 63 X50 | 150 | 65 | 63 | 5.8 | 4.6 | .142 |

| 63 X 40 | 150 | 65 | 57 | 5.8 | 3.7 | .144 |

| 63 X 32 | 150 | 65 | 53 | 5.8 | 3.0 | .110 |

| 63 X 25 | 150 | 65 | 52 | 5.8 | 3.0 | .100 |

| 75 X 63 | 170 | 72 | 65 | 6.8 | 5.8 | .230 |

| 75 X 50 | 170 | 72 | 63 | 6.8 | 4.6 | .190 |

| 75 X 40 | 170 | 72 | 57 | 6.8 | 3.7 | .180 |

| 75 X 32 | 170 | 72 | 53 | 6.8 | 3.0 | .165 |

| 90 X 75 | 190 | 81 | 70 | 8.2 | 6.8 | .360 |

| 90 X 63 | 190 | 81 | 65 | 8.2 | 5.8 | .320 |

| 90 X 50 | 190 | 81 | 63 | 8.2 | 4.6 | .290 |

| 110 X 90 | 205 | 86 | 81 | 10 | 8.2 | .593 |

| 110 X 75 | 205 | 86 | 70 | 10 | 8.0 | .520 |

| 110 X 63 | 205 | 86 | 65 | 10 | 5.8 | .470 |

| 125 X 110 | 215 | 92 | 86 | 11.4 | 10 | .760 |

| 125 X 90 | 215 | 92 | 81 | 11.4 | 8.2 | .680 |

| 125 X 75 | 215 | 92 | 70 | 11.4 | 6.8 | .650 |

| 125 X 63 | 215 | 92 | 65 | 11.4 | 5.8 | .530 |

| 140 X 125 | 225 | 96 | 62 | 12.7 | 11.4 | 1.130 |

| 140 X 110 | 225 | 96 | 86 | 12.7 | 10.1 | 1.020 |

| 140 X 90 | 225 | 96 | 81 | 12.7 | 8.2 | .890 |

| 140 X 75 | 225 | 96 | 72 | 12.7 | 6.8 | .820 |

| 160 X 140 | 245 | 102 | 96 | 14.6 | 12.7 | 1.590 |

| 160 X 125 | 245 | 102 | 92 | 14.6 | 11.4 | 1.440 |

| 160 X 110 | 245 | 102 | 86 | 14.6 | 10 | 1.320 |

| 160 X 90 | 245 | 102 | 81 | 14.6 | 8.2 | 1.18 |

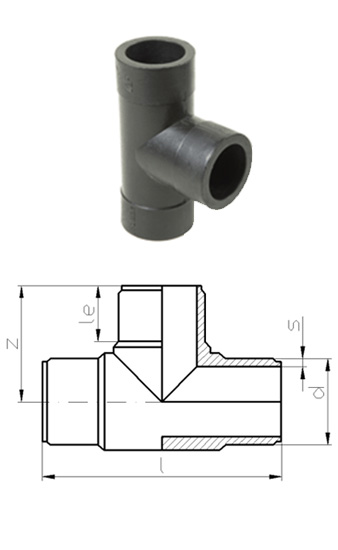

Equal tee – HDPE

Specifications – PE 100, PN 16, SDR 11, S5

Butt welding, injection molded

| d (mm) | l (mm) | le (mm) | z (mm) | s (mm) | Weight kg/pc |

|---|---|---|---|---|---|

| 63 | 230 | 65 | 115 | 5.8 | .370 |

| 75 | 264 | 72 | 132 | 6.8 | .550 |

| 90 | 301 | 81 | 150 | 5.4 | .710 |

| 110 | 330 | 86 | 165 | 6.6 | 1.030 |

| 125 | 366 | 93 | 183 | 7.4 | 1.540 |

| 140 | 380 | 97 | 190 | 8.3 | 2.110 |

| 160 | 420 | 103 | 210 | 9.5 | 2.700 |

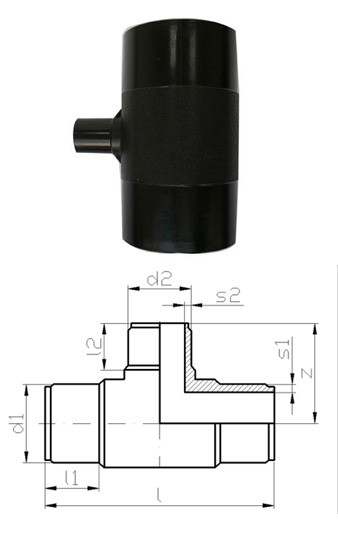

Reducing tee – HDPE

Specifications – PE 100, PN 16, SDR 11, S5

Butt welding, injection molded

| d1/d2 (mm) | l (mm) | l1 (mm) | l2 (mm) | z (mm) | s1 | s2 | Weight kg/pc |

|---|---|---|---|---|---|---|---|

| 63 X50 | 230 | 65 | 57 | 108 | 5.8 | 4.6 | .340 |

| 63 X 40 | 230 | 65 | 52 | 103 | 5.8 | 3.7 | .320 |

| 63 X 32 | 230 | 65 | 48 | 98 | 5.8 | 3.0 | .300 |

| 75 X 63 | 264 | 72 | 65 | 125 | 6.8 | 5.8 | .520 |

| 75 X 50 | 264 | 72 | 57 | 117 | 6.8 | 4.6 | .510 |

| 75 X 40 | 264 | 72 | 52 | 112 | 6.8 | 3.7 | .500 |

| 75 X 32 | 264 | 72 | 48 | 108 | 6.8 | 3.0 | .490 |

| 90 X 75 | 301 | 81 | 72 | 141 | 8.2 | 6.8 | .840 |

| 90 X 63 | 301 | 81 | 65 | 134 | 8.2 | 5.8 | .810 |

| 90 X 50 | 301 | 81 | 57 | 126 | 8.2 | 4.6 | .800 |

| 110 X 90 | 330 | 86 | 81 | 160 | 10 | 8.2 | 1.390 |

| 110 X 75 | 330 | 86 | 72 | 151 | 10 | 6.8 | 1.290 |

| 110 X 63 | 330 | 86 | 65 | 144 | 10 | 5.8 | 1.240 |

| 110 X 50 | 330 | 86 | 57 | 136 | 10 | 4.6 | 1.230 |

| 125 X 110 | 366 | 93 | 86 | 176 | 11.4 | 10 | 2.090 |

| 125 X 90 | 366 | 93 | 81 | 168 | 11.4 | 8.2 | 2.000 |

| 140 X 125 | 380 | 97 | 93 | 183 | 12.7 | 11.4 | 3.00 |

| 140 X 110 | 380 | 97 | 86 | 179 | 12.7 | 10 | 2.90 |

| 160 X 125 | 420 | 103 | 93 | 199 | 14.6 | 11.4 | 3.40 |

| 160 X 110 | 420 | 103 | 86 | 193 | 14.6 | 10 | 3.30 |

| 160 X 90 | 420 | 103 | 81 | 188 | 14.6 | 8.2 | 3.20 |

| 160 X 75 | 420 | 103 | 72 | 179 | 14.6 | 6.8 | 3.90 |

| 160 X 63 | 420 | 103 | 65 | 172 | 14.6 | 5.8 | 3.04 |

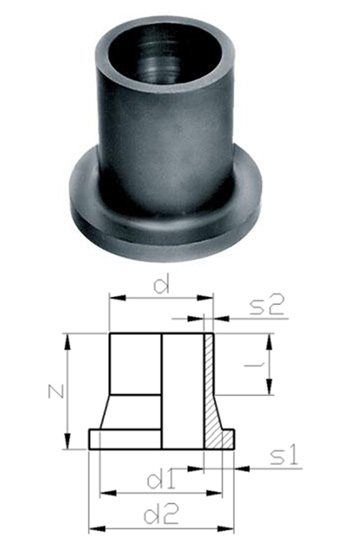

Flange adapter – HDPE

Specifications – PE 100, PN 10, SDR 17, S8

Butt welding, injection molded

| d (mm) | d1 (mm) | d2 (mm) | l(mm) | z (mm) | s1 | s2 | Weight kg/pc |

|---|---|---|---|---|---|---|---|

| 90 | 106 | 138 | 99 | 132 | 17 | 8.2 | .430 |

| 110 | 126 | 158 | 120 | 157 | 18 | 10 | .700 |

| 125 | 132 | 173 | 123 | 170 | 25 | 11.4 | .875 |

| 140 | 155 | 188 | 130 | 175 | 25 | 12.7 | 1.30 |

| 160 | 176 | 212 | 133 | 180 | 25 | 14.6 | 1.62 |

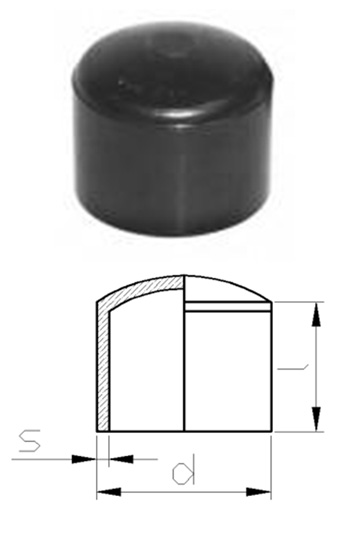

END CAP – HDPE

Specifications – PE 100, PN 16, SDR 11, S5

| d (mm) | l (mm) | s (mm) | Weight kg/pc. |

|---|---|---|---|

| 63 | 57 | 4.6 | .050 |

| 75 | 72 | 6.8 | .140 |

| 90 | 81 | 8.2 | .220 |

| 110 | 86 | 10 | .340 |

| 125 | 93 | 11.4 | .485 |

| 140 | 97 | 12.7 | .680 |

| 160 | 103 | 14.6 | .950 |

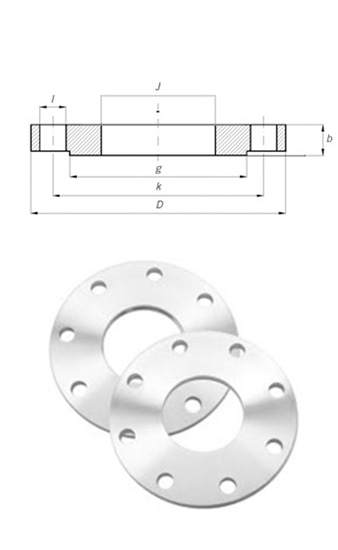

FLANGE – MILD STEEL

Specifications – PE 100, PN 16, SDR 11, S5

| Size | Dia | PCD | Bore Dia | Thick | Bolt hole Dia | No of Bolt hole |

|---|---|---|---|---|---|---|

| 63 | 165 | 125 | 64-65 | 7 | 19 | 4 |

| 75 | 185 | 145 | 76-77 | 7 | 19 | 4 |

| 90 | 200 | 160 | 91-92 | 9.5 | 19 | 4 |

| 110 | 220 | 180 | 112-113 | 9.5 | 19 | 8 |

| 125 | 250 | 210 | 127-128 | 11 | 19 | 8 |

| 140 | 250 | 210 | 142-143 | 12.5 | 19 | 8 |

| 160 | 200 | 160 | 91-92 | 12.5 | 19 | 8 |

We have established ourselves as one of the eminent HDPE Fabricated Fitting manufacturers of India. Owing to the superior quality and performance, our products are highly demanded by the clients. Clients can avail our highly density Polyethylene Pipe Fitting in various sizes and dimensions to meet their specific application requirements. We also fabricate & supply all types of HDPE Pipe fittings like Tees, Bends, Puddle Flanges etc. & they can also be customized as per the requirement set by the clients.

Features:

Specifications: